MESURE DIRECTE DU CHANGEMENT DE L’INDICE DE RÉFRACTION DES GUIDES D’ONDES CAF2 À DOUBLE PISTE

Dans le prolongement de la caractérisation des propriétés des guides d’ondes, le chapitre 6 présente les mesures directes de l’indice de réfraction des guides d’ondes mettant en œuvre la technique de microscopie à contraste de phase ainsi qu’une approche par diffraction de Fresnel pour déterminer la carte tridimensionnelle, 3D, de l’indice de réfraction du cristal CaF2 dans le voisinage des pistes modifiées. La section 6.1 présente brièvement diverses techniques de mesure du changement de l’indice de réfraction et l’avantage comparatif de l’interférométrie par décalage latéral en quadriondes, QWLSI, qui est une nouvelle application de la microscopie par imagerie en phase pour la détection du front d’onde. Les sections 6.2 et 6.3 présentent lathéorie et le montage expérimental de l’IQEEQ, respectivement. Les mesures OPD des guides d’ondes à double voie utilisant l’IQEEQ sont présentées à la section 6.4. La section 6.5 présente une discussion détaillée sur l’effet de la diffraction de Fresnel sur les mesures OPD pour la détermination de l’épaisseur des éléments des guides d’ondes contribuant à la mesure de différence de phase. De plus, le profil complet de l’indice de réfraction 3D est présenté.

Enfin, la section 6.6 confirme cette nouvelle approche pour la mesure du changement de l’indice de réfraction des guides d’ondes à double piste à l’intérieur des cristaux en comparant les profils de champ de mode de la simulation, obtenu par le solveur en mode propre à différence finie (FDE), et les résultats expérimentaux du chapitre précédent.

Jusqu’à présent, plusieurs tentatives ont été faites pour déterminer le changement d’indice de réfraction des guides d’ondes modifiés par laser ultra-court à l’intérieur des cristaux. Cela a étéun grand défi. Dans ce chapitre, nous avons présenté une nouvelle approche pour la mesure du changement de l’indice de réfraction et nous avons démontré expérimentalement la précision des résultats.

Thermalization and Heat Dissipation

For sub picosecond pulses, the processes of energy absorption and ionization are morethouroughly understood than the plasma energy dissipation process [36]. Generally in lightmatter interaction of homogenous dielectric materials, electron-electron and electron-phonon coupling are the main plasma relaxation mechanisms [37], while thermal diffusion and shockwave generation are the primary mechanisms of energy dissipation [36].

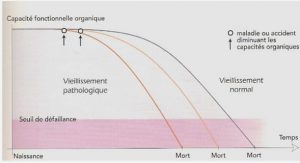

The first step of energy absorption is the relaxation of the electrons by carrier-carrier scattering, or electron-electron coupling, which results by thermalization of electrons. This process is highly dependent on the carrier density [15]. For lower excitation densities, the electrons basically interact with the equilibrium part of the electron distribution while for higher excitation densities, multiple collisions between non-equilibrium electrons dominate the process leading to rapid thermalization [37]. This thermalization process occurs within hundreds of femtoseconds and the lattice structure is still largely undisturbed. The second stage of the thermalization process is related with the relaxation mechanism of the energy transfer of the electrons to the lattice in dielectric bulk materials. Temporally, this energy transfer process happens at the end of the laser pulse by efficient electron-lattice scattering. This process is called electron-phonon coupling and it is characterized by a temperature exchange process between electrons and phonons. This stage of the thermalization mechanism ty pically occurs on the time scale of 1-100 ps, depending on electron-phonon coupling strength of the material [15].

For a given pulse in the femtosecond regime, the electrons in the conduction band are heated much faster than they are cooled by phonon emission, and the pulse ends before the electrons thermally excite any ions [22]. It is only after the laser pulse is gone that thermal energy from “hot” electrons is deposited in shock-like form to the lattice [9]. This results in a shockwave or pressure within a couple of nanoseconds [22]. This is followed by diffusion of the thermal energy out of the focal volume (voxel) over a microsecond scale [9], [15].

It is this relative rate of energy deposition (shockwave generation) and thermal diffusion inside the focal volume of the lattice that primarily determine the damage threshold of the dielectricmaterial during micromachining while the relative dominant process between the two probablydepends on pulse fluence and repetition rate [9], [36]. For sufficiently high irradiance, the above thermal processes give rise to a temperature increase of the lattice inside the focal volume to several hundred or even thousands of degrees [15] leading to phase transitions, fusion and explosion in the latter part of the thermodynamic process. While the aforementioned processes are well understood and largely material independent processes, the thermal and structural processes that follow leading to permanent modifications are material dependent and are still the subject of intense research. These processes result in physical, chemical and structural changes like densification [38], stress [39], and color center formation [40] particular to the material at micro volumes [26], [36].

For example, the refractive index modification induced within bulk materials is strongly dependent on the exact material composition and also the direct laser writing (DLW) parameters, especially on the repetition rate of the pulses [26].

The repetition rate or frequency of the laser is the main driving force behind the thermal effects within the focal volume in which the thermal diffusion relaxation time can be determined by the thermal diffusion coefficient, Dth, as [15]:

Parameters Affecting the Femtosecond Laser–Matter

Interaction

In addition to the repetition rate of the laser source, micro-modifications inside crystals also depend on other irradiations parameters as well as physical material properties such as bandgap, dispersion, ionization rates and so on. To mention just a few: – Focusing conditions, i.e. numerical aperture of the microscope objective (NA): can determine the energy needed to reach a threshold (Eth). With the threshold intensity andthe critical power for self-focusing as free parameters, for diffraction-limited focusing with weak self-focusing, Eth can be expressed as.

Types of Modifications in Crystals

In general, following the irradiation of femtosecond pulses inside crystals, the induced morphological modifications along the tracks can be divided into two categories: smooth andsevere damage regimes, or more commonly type I and type II modifications, respectively. Thetype I and II classification has recently been adopted for both crystals and glasses based on reference [48]. However, in the case of crystals, the type II classification scheme can be expanded to include type III waveguide configurations which are basically depressed cladding waveguide structures as it will be explained in section 5.1.

Properties of Crystals

The term “crystal” derives from the Greek word “Krystallos” which means “ice”. In fact, the name is figurative and it is obvious that ice in the form of snowflakes or glaciers is crystalline. However, the word crystal includes a broad category of other forms of solid state matter, for example rock crystals.

Consequently, in the standard form the term “crystal” can be defined as solid-state bodies which are homogenous, anisotropic, and are composed of constituents that are strictly threedimensional periodically ordered [76]. Thus, technically, crystals can be described as a lattice with a basis added to each lattice site as shown in Figure 2-10.

Crystals of Interest: Nd:YAG and CaF2

Crystals can be divided into 2 groups based on how the velocity of light of a particular wavelength propagates in the material. Crystals whose refractive index does not depend on the direction that the light travels are called isotropic materials. While crystals whose refractive index does depend on the direction that the light travels, polarization, are called anisotropic materials. These types of materials will have a range of refractive indices between two extreme values for each wavelength.

The tetragonal and hexagonal crystal systems are uniaxial and are characterized by 2 extreme refractive indices for each wavelength. While the triclinic, monoclinic, and orthorhombic crystal systems are biaxial and are characterized by 3 refractive indices, one of which is intermediate between the other two.

As it was described above, isotropic crystalline materials exhibit a uniform refractive index in any arbitrary direction. Thus, owing to this direction independent uniform property, optical specificities and restrictions of low-symmetry crystal optics are neglected for cubic crystals which enables a more simplified systematic approach to study modifications due to femtosecond DLW inside crystals along the damaged tracks. In this thesis work, the focus is on more and better understanding and an approach for qualitative and quantitative characterizations in both waveguiding and luminescence properties of modified cubic crystals, namely Yttrium Aluminum Garnet (YAG) and Calcium Fluoride (CaF2).

Calcium fluoride (CaF2) is a dielectric crystal which crystallizes in a cubic fluorite structure, space group Fmm3 [81]. The cation positions correspond to the closest packing and each unit cell has four Ca atoms and eight F atoms as shown in Figure 2-15. With its high transparency in a broad wavelength range, a low refractive index, and a low phonon energy, CaF2 is used as commercial optics material from the infrared to the ultraviolet region, such as for windows [82].

State-of-the-art of Direct Laser Writing inside Crystals

Femtosecond laser micromachined crystalline waveguides can be implemented in many different technological issues of photonics. Some of the components demonstrated for integrated optics inside crystals are:

• Electro-optic modulators: have been fabricated with a Mach–Zehnder interferometer (MZI) configuration in LiNbO3 crystals [95]–[98].

• Three-dimensional waveguide splitters: pave a way to produce direct-pump compact integrated laser devices on chip scales for beam splitting in dielectric laser crystals for various photonic applications. With a photonic-lattice-like cladding approach, Nd:YAG splitters capable of 1 to 2 and 1 to 4 beam splitting, for pumps at 808 nm and 1064 nm wavelength with slope efficiencies of 34% and 22% were realized [99].

• Frequency converters: can be realized in nonlinear crystals. As compared to bulk, waveguides enhance the efficiencies of second-harmonic or higher-order generation. Readers are encouraged to refer to Table 1 of [16] which summarizes literatures for SHG in fs-laser micromachined crystal waveguides.

• Waveguide lasers: possess lower lasing thresholds, comparable efficiencies and compact geometries as compare to bulk solid state lasers. Both type II and type III waveguide configurations have been realized and intensively studied. Readers might find a complete list of reviews for waveguide lasers inside crystals in Table 2 of [16].

In relation to our crystals of interest, a number of works have reported on ytterbium and neodymium doped YAG crystals. Slope efficiencies above 70% [100], also known as a parasitic process achieved by simply polishing the end facets, and continuous wave output powers of more than 5 W were reported by T. Calmano et al. [101]–[106]. The same group demonstrated a passively Q-switched waveguide laser with repetition rate of 300 kHz at 300 mW [107]. While this group has been more dedicated on type II waveguide configurations, the group of A. Okhrimchuk (Moscow, Russia) et al., focused more on depressed cladding, type III, waveguides inside YAG crystals [60], [108], [109]. They have demonstrated a microchip type III waveguide laser operating in Q-switched mode [109] and a 11-GHz waveguide laser mode-locked with a single layer of graphene [110]. Beside these two groups, a number of studies and characterization of waveguides inside doped YAG samples have been demonstrated, readers are encouraged to refer to [59], [108], [111]–[114]. While there are a number of studies about waveguides inside YAG, the study of femtosecond laser written waveguides inside CaF2 has been so far ignored and only a few works have been performed [75]. Recently, R. Graf et al. categorizes the type of modifications inside CaF2 as pearl-chain type [115] which makes it difficult to achieve waveguiding [116]. The only significant recent work was the fabrication of Yb,Na:CaF2 depressed cladding waveguides produced by the DLW technology [117], in which dual-wavelength laser emissions, at 1013.9 nm and 1027.9 nm, with an optical-to-optical conversion efficiency as high as 45.3% and a pulse energy of 0.13 μJ was demonstrated. Just recently, Babu et al. reported double track cladding inside Nd 3+ , Y 3+ co-doped CaF2 crystals with refractive index, birefringence, transmission loss and micro-luminescence studies as a function of the double track separation [118]. In the upcoming chapters, the work of this thesis on double track waveguides achieved both inside Yb-doped YAG and undoped CaF2 crystals will be presented. To the best of our knowledge we have demonstrated the first double track waveguides inside CaF2 samples [119] with good guiding properties. Moreover, a detailed description for new characterization approaches of those waveguides is given, which opens a new venue in the field of direct laser writing in crystals and in other dielectric materials.

Experiment in Femtosecond Laser Structuring

Experimental Set-up

In its fundamental form, a femtosecond laser writing setup consists of a high-power radiation source, a beam delivery system and a programmable 3-axis stage. Figure 3-1 shows the basic components of the direct laser writing setup from pulse beam generation to delivery of the pulse at the focal volume inside the dielectric crystal sample.

High Power Source

The femtosecond laser beam, which is utilized for most of the work, was delivered by RegA 9000 laser system, from Coherent Inc. the laser system chain is constituted by a femtosecond oscillator, a regenerative amplifier and a stretcher/compressor.

Femtosecond Oscillator

The Chameleon Vision S, customized, is pumped at 532 nm by a Verdi solid state laser, to produce an 80-MHz pulse train centered at 800 nm with pulse energies on the order of 40 nJ. The mode-locking occurs via Kerr-lens mode-locking applying a material exhibiting the nonlinear Kerr effect reducing the beam size when mode-locked together with a slit that introduces losses to larger, continuous wave beams.

The mode-locking is initiated by a reflective starter assembly that can modulate the cavity length and phase locks the longitudinal modes of the laser. The final pulse width is establisheddue to an interplay of pulse broadening due to self-phase modulation and negative dispersion induced from a prism pair inside the cavity to achieve soliton mode-locked pulses with a duration of 75 fs.

Beam and Pulse Control

Beam Shaping and Polarization

The polarization of the linearly light ejected from the compressor module is rotated using the half-wave plate to give maximum optimized efficient output at the acousto-optic modulator (AOM). A telescope arrangement of f1 and f2 lenses is used to give an optimum beam diameter at the AOM core, 2 mm x 2mm, and at the microscope objective diaphragm, 6 mm to 10 mm, in the meantime, the microscope objective tightly focuses the beam inside the sample. It is worth to note that the beam shaping arrangement described above results in a polarization parallel to the designated y-axis at the 3D-stage.

Pulse Shaping and Picking

The pulse energy was modulated by a computer controlled arbitrary waveform generator, Agilent 33250A, which drives the fixed frequency source that generates the RF signal for the AOM with a first order frequency shift of 110 MHz. Consequently, this provides the user with complete flexible control of energy and exposure time of the pulse train on to the sample down to single pulse picking.

D Trajectory

The three dimensional trajectory of the writing tracks is achieved by placing the sample on a slide which is attached to micro-controlled Newport Corporation X-Y-Z stages, XMS50, with a spatial resolution of 0.04 µm along the predetermined path.

Power and Trajectory Control

An XPS Universal Motion controller from Newport Corporation is used to offer a configuration wizard for the XMS50 three-dimensional stages while the Agilent 33250A provides a configuration tool for RF supply to the AOM. The laboratory grown IGOR program with the Graphic User Interface (GUI) is used to control both the power, by setting the RF voltage of the AOM, and 3D trajectory using the XPS server that manages the assigned line-arc trajectory motion groups of the three-dimensional stage.

Protocol for Laser Structuring

In addition to the aforementioned components, a detailed procedure for the fabrication is explained below:

– The RegA chain, with RegA 9000 seeded with the Chameleon Vision S, is turned on and the system normal start up is controlled by the oscilloscope output connected to the RegA system control.

Fabrication of Waveguides

The femtosecond laser inscription setup and protocol of the previous chapter is applied on two differently cut CaF2 samples to inscribe double track waveguides, which will be discussed in Sections 4.1 and 4.2. Although the main task was to identify the writing parameters , the crystal samples which were cut along the defined principal axes exhibited anomalies, namely smooth modification and non-reciprocal writing, which were reported only in a handful cases so far. This will be detailed in Section 4.3.

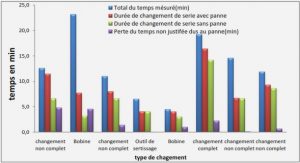

Modification Threshold and Crack Formation

The GUI based software developed using IGOR allows flexible control of the modulated power of the pulses by the RF function generator and arc-line trajectories using the XPS server. Once the beam is focused inside the sample, we can identify the damage threshold using a matrix of number of pulses and the AOM RF voltage. In transversal writing of tracks, the number of pulses crossing each point can be related with the speed of writing as a product of time to intercept a point and repetition rate of the laser. The speed of writing (v) can be given as:

Waveguide Inscription

In parallel to the threshold of modification and crack formation, waveguide tracks were studied, or short lines, i.e. fabrication inside two groups of single-crystal samples of undoped CaF2. The first sample had faces parallel to some main planes, i.e. polished faces parallel to [112 ̅ ], [1 ̅ 10] and [111] planes (Sample A) as shown in Figure 4-2 (a). While the second sample had faces randomly cut and parallel to [043 ̅ ], [13 ̅ 4 ̅ ] and [611] planes (Sample B) as shown in Figure 4-2 (b). The x and y axes of CaF2 are assigned as the short and longer sides in which the x axis of the crystal is perpendicular to the plane [1 ̅ 10] and [13 ̅ 4 ̅ ] while the y-axis of the crystal is perpendicular to the plane [111] and [611] in Sample A and Sample B, respectively.

A number of short tracks, of 150 µm in length, were inscribed 150 µm below the surface with the scan speed varying between 10 µm/s to 1000 µm/s and with various pulse energies ranging between 0.36 µJ to 0.72 µJ, which correspond to numbers of pulses per spot (N) between 570 to 57000 and fluences (F) between 8.7 J/cm 2 to 17.5 J/cm 2, respectively. We were surprised to notice smooth modification in the case of Sample A for an approximate scanning speed between 200 µm/s to 300 µm/s for certain polarizations with respect to the crystal axes, energy and direction of writing. In addition, this was not observed in the case of the Sample B in which low loss waveguides were inscribed as it was discussed in the section 4.2 and Chapter 5.

|

Table des matières

RÉSUMÉ

ABSTRACT

ACKNOWLEDGEMENTS

TABLE OF CONTENTS

SYNOPSIS

NOMENCLATURE

LIST OF FIGURES

LIST OF TABLES

1 INTRODUCTION

1.1 MOTIVATION AND AIM

2 LASER-MATTER INTERACTION IN CRYSTALS

2.1 FUNDAMENTAL PRINCIPLES OF LASER-MATTER INTERACTION

2.1.1 Nonlinear Propagation and Filamentation

2.1.2 Nonlinear Photon Absorption and Propagation

2.1.3 Thermalization and Heat Dissipation

2.1.4 Parameters Affecting the Femtosecond Laser–Matter Interaction

2.2 TYPES OF MODIFICATIONS IN CRYSTALS

2.3 PROPERTIES OF CRYSTALS

2.4 CRYSTALS OF INTEREST: ND:YAG AND CAF2

2.5 STATE-OF-THE-ART OF DIRECT LASER WRITING INSIDE CRYSTALS

3 EXPERIMENT IN FEMTOSECOND LASER STRUCTURING

3.1 EXPERIMENTAL SET-UP

3.1.1 High Power Source

3.1.2 Beam and Pulse Control

3.1.3 3D Trajectory

3.1.4 Power and Trajectory Control

3.2 PROTOCOL FOR LASER STRUCTURING

4 FABRICATION OF WAVEGUIDES

4.1 MODIFICATION THRESHOLD AND CRACK FORMATION

4.2 WAVEGUIDE INSCRIPTION

4.3 SMOOTH MODIFICATIONS AND NON-RECIPROCITY OF DLW INSIDE CAF2

4.3.1 Smooth Modification

4.3.2 Non-reciprocity

4.4 CONCLUSION

5 GUIDING CHARACTERISTICS OF THE WAVEGUIDES

5.1 INTRODUCTION TO WAVEGUIDING

5.2 GEOMETRIES OF WAVEGUIDES IN CRYSTALS

5.3 MODES IN WAVEGUIDES

5.3.1 Setup

5.3.2 Mode Field Diameter Measurements

5.4 TRANSMISSION LOSSES

5.4.1 Modeling Guided and Unguided Modes

5.4.2 Setup

5.4.3 Calculation and Result

5.5 POLARIZATION BEHAVIOR OF THE WAVEGUIDES

5.6 CONCLUSION

6 REFRACTIVE INDEX CHANGE MEASUREMENT OF DOUBLE TRACK CAF2 WAVEGUIDES

6.1 REFRACTIVE INDEX MEASUREMENT TECHNIQUES

6.2 PRINCIPLE OF QUADRIWAVE LATERAL SHEARING INTERFEROMETERY (QWLSI)

6.3 QWLSI EXPERIMENTAL SETUP

6.4 OPD MEASUREMENTS

6.5 OPD MEASUREMENTS TO 3D REFRACTIVE INDEX MAP

6.5.1 Thickness of Longitudinal Elements

6.5.2 Thickness of Lateral Elements

6.5.3 3D Refractive Index Change Profile

6.6 SIMULATION

6.6.1 Method of Simulation

6.6.2 Comparison between Experiment and Simulation of Guided Modes

6.7 CONCLUSIONS

7 CONCLUSION AND FUTURE WORK

APPENDIX A

BIBLIOGRAPHY